Our History

Deepward means think deep, move forward! Let's work together and enjoy the happiness in eyewear path!

Competitive price + High quality + Fast delivery + Best service

Shenzhen Deepward has been established in 2010, located in Henggang town, Shenzhen, one city where mainly produce high quality eyewear by gathering sophisticated industrial chain service and outstanding designs started from here.

Deepward mainly produce high quality handmade acetate eyewear, metal eyewear, Titanium eyewear, Carbon fiber eyewear, and all kinds of different material optical frame and sunglasses. We have around 80-100 workers, 3000 square meters workshop. OEM order has a proportion of 90% among whole Deepward orders, balance are for ODM orders.

Our customer profile is mainly from independent eyewear brands, since these brands are strict to quality from all kinds of details, this is what Deeward is good at. The reason why Deepward can produce high quality eyeweas is that nearly 75% workers have been working in Deepward for more than 8 years. This is the most important reason which can guarantee the quality level stably. Deepward has provided the highest quality eyewear and the most complete services to more than 35 clients in more than 15 countries from the world.

Our company's story begins with a deep love for the craft of acetate eyewear. Relying on our rich experience in the glasses manufacturing industry and our keen insight into new materials and technologies, the founder decided to create a company focused on the production of high-quality glasses. In its early days, the company won praise from the industry for its superb craftsmanship of handmade acetate eyewear, strict quality control and excellent customer service.As the company develops, we continue to introduce new technologies and materials to improve product quality and design diversity. We successfully developed metal eyewear production flow in 2015, which quickly is recognized by customers due to its exquisite quality. Since then, we have successively add titanium eyewear and carbon fiber frames production. More and more customers relied on Deepward.

Our Factory

PART MACHINES WE HAVE

Temple Shooting

Machines

In order to make acetate temple be out of shrink and affect to wear, it is necessary to put core wire inside the actate temples. There is precise drilling and core wire installation, the frame and the temples are well connected, this is helpful to make the glasses more durable and reducing the risk of loosening. Core wire shooting process is one important production step for producing high-quality eyeglass for sure,

Our company produced lots of customized core wire for our korea customers, which request complicated core wire shooting skills, otherwise there are lots of problems among the whole production process.

Tumbling

Machines

The tumbling process in eyeglass manufacturing can enhances production efficiency. Through continuous operation with automated equipment, it reduces manual intervention time and errors. We are always looking for the way to reduce production cost without affect quality, our company has invested over USD 150,000 in research and development, continuously improving tumbling materials and machinery to reduce handmade polishing cost. Although we are not a large-scale factory, our company owns 40 TUMBLERS. Our mission is to maintain the unique charm of each eyeglass frame while ensuring its surface becomes smoother and more refined.

Laser Welding

Machines

Laser weldig can work on very small details, also it has better welding accuracy by comparing with regular welding technique. when customers provide some complex eyewear designs to us for working, we will consider laser welding for meeting customers' requirement. Normally we use it in situations where traditional welding machines cannot meet the welding requirements or do not achieve the same quality as laser welding. Previously, we don't make laser welding in our own workshop directly and mainly cooperate with other professional outsource department, but the quality was not stable and hard to meet our requirements. To maintain our high-quality standards, we purchased 2 laser welding machines to be operated by our internal staff.

Ti Welding

Machine

Normally we use Argon welding to produce Titanium material eyeglasses, this welding method guarantees high-quality finishes for eyeglass frames. Our company has been producing titanium frames for 15 years. Throughout the production process, we have maintained excellent control over cleanliness, welding accuracy, and welding production efficiency, providing a strong guarantee for the production of high-quality eyeglasses. Currently, we have 8 argon welding machines for titanium frame welding.

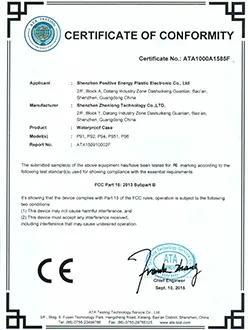

CERTIFICATES WE HAVE

Deepward is dedicated to producing high-quality eyewear and has obtained multiple international certifications to ensure the eyewear we produce meets global market standards and requirements.

- CE certification: ensuring eyewear comply with the safety, health, and environmental protection requirements of the European Union;

- ROHS certification: guaranteeing that eyewear meet EU standards for hazardous substances;

- FDA certification: ensuring the safety and effectiveness of sunglasses in the U.S. market;

- BSCI certification: ensuring eyewear processes adhere to social responsibility and ethical standards.

These certifications not only demonstrate the superior quality and safety of eyewear but also reflect our commitment to environmental protection and social responsibility. Choosing our company for eyewear manufacturing means choosing high-quality eyewear that is safe, reliable, and sustainably developed.

CE

ISO

BSCI

FDA

CE of each sku

CE of each sku

SERVICE WE PROVIDE

Try to reply you within 10 minutes

As we all know that the eyewear lead time is really long than regular industry which last around 4-5 months since design to final shipment, our company is always dedicated to providing exceptional service to ensure everthing go smoohtly and walk ahead of others, our professional team offers comprehensive consultations and after-sale support, responding to customer needs 24H*7 DAYS. Hope every customer receives the best purchasing experience after confirmed to cooperate with Deepward, one company who mainly produce high quality eyewear for independent eyewear brands.

01

Pre-sale service

Conduct quality, price, MOQ, technical issues and so on for freee. We can provide free samples to potential customers for checking our quality, sometimes we are glad to produce customized samples for customers for free if necessary.

02

Customized Service

We can provide customized service to customers, we mainly produce OEM order for independent eyewear brands, the customized service includes acetate color customization, shape customization, metal components customization, for example, core wire, metal trim, metal temples, etc.

03

After-sales service

We can provide repairment for free once customers find defects and can't accept, or we can issue credit to customers for deducting the amount from next order if the problems happened due to our company's quality issue. Our final goal is to eliminate quality complaints

LAB TEST WE DO

Artificial Sweat Test

Artificial sweat testing is used to check the corrosion resistance and durability of eyewear materials. This test copy the composition of human sweat by putting the eyewear in an artificial sweat container under specific temperature and humidity conditions. Here is rough test method: the test material we use includes sodium chloride, urea, and lactic acid, set the pH of human sweat (usually between 4 and 6). The testing temperature is generally set between 30°C and 40°C, time last from 48 to 72 hours. After the test, the eyewear should show no significant corrosion, discoloration, or structural damage, ensuring its durability and safety in actual use. Our company's metal plating can usually pass 48H artificial sweat testing.

Polarization Test

A polarization tester is based on the optical principle of polarization phenomenon. It uses the characteristics of polarizer to separate and measure polarized light in different directions. In this way, we can see how the polarized sun lenses are placed in eyewear frame, and improve the visual clarity and comfort.

Here is rough test method: placing the polarized sun lenses in the tester, rotating the lenses, and adjusting the light source to measure their light transmittance and polarization angle. The polarization tester will show the intensity and direction of the light.

Testing standards request the polarized lenses' light transmittance to be set within a specific range, and the polarization angle should be kept within +/- 1°..

Welding Test

Normally lots of experienced production manager will check the welding strength by bending the frame through hands, however our company always apply scientific methods to check the welding strenght. The machine we use is welding tester, it is used to check the quality and strength of the welding points. Here is rough test method: Apply a force of 10 to 20 Newtons to the welded joints, repeatedly bending them at an angle of 30 to 45 degrees again and again to check cracks, fractures, or looseness. Standards require the testing equipment to precisely control the applied force and angle. Through this test, we can see the welding strength of each eyeglass frames, and make sure the eyeglasses be wear safely and stably during dairly life.

The Hinge Durability Test

The hinge durability test for eyeglass frames is used to check the long-term durability of hinges. Normally, we will open and close the hinges again and again to achieve the number of times an eyeglass hinge would be used in daily life, checking the looseness, breakage, or failure.

Here is rought test method: a force of 0.5 to 1.0 Newton-meters (Nm) is applied, open and close the hinge time by time at an angle of approximately 90 to 135 degrees. Generally, a minimum of 10,000 opening and closing times is required to pass the test. The screwless hinges produced by our company can endure up to 30,000 opening and closing cycles without showing any signs of looseness, breakage, or failure.

Drop Ball Test

Belive that all eyewear people know drop ball test, this drop ball test is used to check the impact resistance of sun lenses, make sure the sunglasses can be wear safely in daily use. Normallly we will drop a steel ball with specific weight from a fixed height, then the ball will strike the sun lens surface, like an accidental impacts. During this step, we will use a 16g steel ball and dropped from a height of 1.27 meters. When the sun lenses should not show any signs of cracking, or separation, and must maintain their optical performance and surface is well kept, then this test pass. Usually, USA Customs requires a drop ball test report for making customs clearance.

Eyewear Size Reading Test

The size reading test is used to check the lens dimensions, so the lens size can be produced according to design specifications, also it is easy for production department to evaluate if the size is workable to move forward. Before the test, our people will use one caliper to measure the lens width, height, and perimeter.The size measurement should be same as the requirements outlined in the CAD drawing, also the lens dimensions should meet CE standards and customer demands. Typically, the actual width of the frame should not exceed more than 5mm size tolerance, and the height of the frame should not exceed than 3mm. Through this test, the production of eyeglass lenses quality is ensured, consumers will feel it is very comfortable to wear frame that deepward produce.

Sunglasses Stress Test

The sun lens stress test is one part of international industry standards, For example, ISO 12312-1 and ANSI Z80.3, especially European customers focus on this kind of test much more, because it is necessary for us as factory to meet market and regulatory requirements, and enhancing customers' eyewear brand credibility. This test is used to make sure that the sun lens will not hurt people's eyes and make sure the wearing comfortability. Stress induced by compression is typically acceptable if located in the B zone; however, if in the A zone, special attention is needed to ensure no significant impact on optical performance.